Description

Standard: BSEN 10002-1, ISO 7500-1, ASTM A370

Tensile & Compression

Universal Testing Machine 100kN Servo Fully Automatic

Universal Testing Machine 100kN is used for measurement & test of mechanical properties & analytical study of metal, non-metal & composite material, such as aviation, petrochemical, machinery manufacture, wire, cable, textile, fiber, plastic, rubber, ceramic, food, medicine packaging, aluminum plastic tube, plastic door & window, geo-textile, film, wood, paper, metal material & manufacture industry, etc.

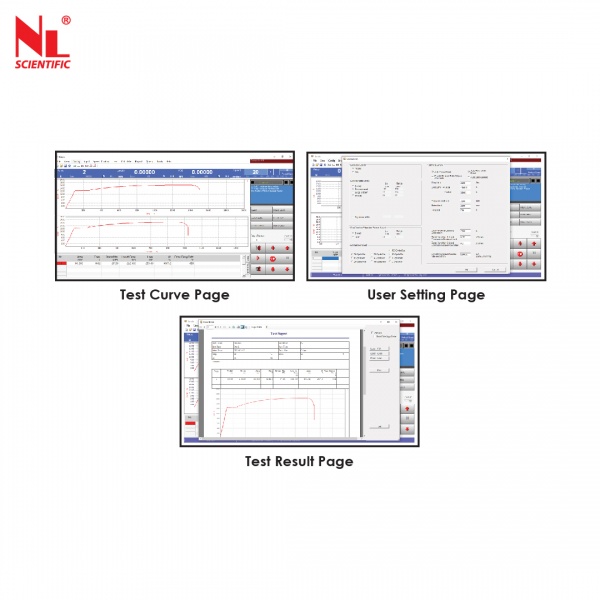

It can record the max. test force, fracture value, yield value, max. compression value automatically. It can also calculate the fracture extension & all kinds of strength values manually. The RA232 connector can have the function of communicating with the computer to do the data work. It is an essential equipment for manufacture, construction unit, product quality supervision & inspection bureau & building material test department. It also could be used in the university for teaching purposes.

TT Servotec Fully Automatic Universal Testing Machine out tester adopts DC speed regulating servomotor & reduction gears as the power source. Its real-time displays test data & test status with an LCD module. A professionally designed servo control system realizes the PWM pulse width modulation control mode. It comes up with test speed closed-loop control mode. It is controlled by a single chip automatically control.